| Items |

DN-1-1/2

1-1/2 Inch (in) Wafer Check Valve

|

DN-2

2 Inch (in) Wafer Check Valve

|

DN-2-1/2

2-1/2 Inch (in) Wafer Check Valve

|

DN-3

3 Inch (in) Wafer Check Valve

|

DN-4

4 Inch (in) Wafer Check Valve

|

|

Description

|

N/A

|

|

Brands

|

N/A

TVI

|

|

Type

|

N/A

Wafer

|

|

Nominal Size

|

N/A

1-1/2 in

|

N/A

2 in

|

N/A

2-1/2 in

|

N/A

3 in

|

N/A

4 in

|

|

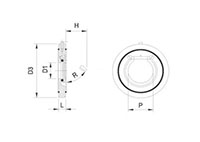

Dimension D1

|

N/A

0.89 in

|

N/A

1.26 in

|

N/A

1.57 in

|

N/A

2.13 in

|

N/A

2.76 in

|

|

Dimension D2

|

N/A

|

|

Dimension D3

|

N/A

3.76 in

|

N/A

4.30 in

|

N/A

5.12 in

|

N/A

5.71 in

|

N/A

6.45 in

|

|

Dimension P

|

N/A

1.38 in

|

N/A

1.77 in

|

N/A

2.36 in

|

N/A

2.83 in

|

N/A

3.54 in

|

|

Dimension L

|

N/A

0.63 in

|

N/A

0.79 in

|

N/A

0.79 in

|

N/A

0.79 in

|

N/A

0.87 in

|

|

Dimension H

|

N/A

0.99 in

|

N/A

1.80 in

|

N/A

2.00 in

|

N/A

2.90 in

|

N/A

3.60 in

|

|

Dimension R

|

N/A

68 in

|

N/A

73 in

|

N/A

75 in

|

N/A

73 in

|

N/A

72 in

|

|

Working Pressure1

|

N/A

145 psi

|

|

Pressure to Open

|

N/A

0.1 psi

|

|

Required Back Pressure

|

N/A

1 psi

|

|

Weight Per Valve

|

N/A

1 lb

|

|

Flow Coefficient Value (Cv)

|

N/A

26

|

N/A

58

|

N/A

77

|

N/A

105

|

N/A

224

|

|

Materials of Construction

|

N/A

Part - Body

Pcs - 1

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Chlorinated Polyvinyl Chloride (CPVC), and Polyvinylidene Fluoride (PVDF)

Part - Flapper

Pcs - 1

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Chlorinated Polyvinyl Chloride (CPVC), and Polyvinylidene Fluoride (PVDF)

Part - Flapper Mounting Screw

Pcs - 1

Material - Polypropylene (PP)

Part - O-Ring

Pcs - 1

Material - Unplasticized Polyvinyl Chloride (UPVC) and Viton®

Part - Installation Device

Pcs - 1

Material - SS 316 Stainless Steel

Part - Spring

Pcs - 1

Material - SS 316 Stainless Steel

|

|

Body and Flapper

|

N/A

Polyvinyl Chloride (PVC), ASTM D-1784

Polypropylene (PP), ASTM D-4101

Polyvinylidene Fluoride (PVDF), ASTM D-3222

|

|

Flapper Mounting Screw

|

N/A

Polypropylene (PP), ASTM D-4101

|

|

Seals (O-Rings)

|

N/A

Ethylene Propylene Diene Monomer (EPDM)

Fluorocarbon, Viton® (Dupont Dow Elastomers)

|

|

Installation Device

|

N/A

316 Stainless Steel

|

|

Connection

|

N/A

Wafer style to fit between ANSI B16.5 Class 150 Flanges

|

|

Options

|

N/A

316 Stainless Steel Spring Assist

Spacer

|

|

Design Advantages

|

N/A

Vertical or Horizontal operation

Economic ~ Simple and durable construction

Compact ~ Requires little space in piping system

Easy Installation ~ Wafer body fits between standard ANSI flanges (2-1/2" & 3"valves require spacers)

Body Construction ~ Light Weight, Chemical Resistant, Non-Corrosive

Available with 316 SS Spring Assist.

|

|

Applications

|

N/A

Water and Waste Treatment

Chemical Industry

Environmental Industry

Process Industry

Systems Engineering

|

|

Testing Procedure

|

N/A

Testing performed on Polyvinyl Chloride (PVC)/Ethylene Propylene Diene Monomer (EPDM) valves at 73 ºF water temperature, non-shock.

|

|

Note

|

N/A

Wafer Checks are not full port valves. R = Disc angle in the open position

|