| Items |

DN-1/2

1/2 Inch (in) Ball Check Valve

|

DN-3/4

3/4 Inch (in) Ball Check Valve

|

DN-1

1 Inch (in) Ball Check Valve

|

DN-1-1/4

1-1/4 Inch (in) Ball Check Valve

|

DN-1-1/2

1-1/2 Inch (in) Ball Check Valve

|

|

Description

|

N/A

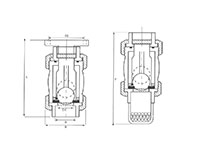

Thermoplastic Ball Check Valves (1/2" - 4") are of all thermoplastic construction. Body has full length ribs for maximum flow, minimum pressure drop, and to eliminate ball sticking and chatter. Ball is of solid thermoplastic material. Seat is full circle and resilient.

|

|

Brands

|

N/A

TVI

|

|

Size

|

N/A

1/2 in

|

N/A

3/4 in

|

N/A

1 in

|

N/A

1-1/4 in

|

N/A

1-1/2 in

|

|

Dimension D1

|

N/A

0.598 in

|

N/A

0.771 in

|

N/A

0.984 in

|

N/A

1.259 in

|

N/A

1.574 in

|

|

Socket Dimension d

|

N/A

0.840 in

|

N/A

1.050 in

|

N/A

1.315 in

|

N/A

1.660 in

|

N/A

1.900 in

|

|

Screw Dimension L

|

N/A

1/2 in

|

N/A

3/4 in

|

N/A

1 in

|

N/A

1-1/4 in

|

N/A

1-1/2 in

|

|

Screw Dimension L (Thread Type)

|

N/A

National Pipe Thread (NPT)

|

|

Socket Dimension

|

N/A

3.976 in

|

N/A

4.527 in

|

N/A

5.354 in

|

N/A

6.732 in

|

N/A

6.732 in

|

|

Screw Dimension

|

N/A

3.976 in

|

N/A

4.527 in

|

N/A

5.354 in

|

N/A

6.732 in

|

N/A

6.732 in

|

|

Flanged Dimension

|

N/A

5.75 in

|

N/A

6.25 in

|

N/A

7.25 in

|

N/A

9.00 in

|

N/A

9.00 in

|

|

Dimension B

|

N/A

2.106 in

|

N/A

2.492 in

|

N/A

2.875 in

|

N/A

3.842 in

|

N/A

3.842 in

|

|

Dimension D2

|

N/A

2.375 in

|

N/A

2.750 in

|

N/A

3.125 in

|

N/A

3.500 in

|

N/A

3.875 in

|

|

Dimension F

|

N/A

5.50 in

|

N/A

6.50 in

|

N/A

7.50 in

|

N/A

9.75 in

|

N/A

9.75 in

|

|

Working Pressure

|

N/A

150 psi

|

|

Materials of Construction1

|

N/A

Part - Body

Pcs - 1

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF), and Chlorinated Polyvinyl Chloride (CPVC)

Part - Ball

Pcs - 1

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF), and Chlorinated Polyvinyl Chloride (CPVC)

Part - Seat Carrier

Pcs - 1

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF), and Chlorinated Polyvinyl Chloride (CPVC)

Part - Connector

Pcs - 2

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF), and Chlorinated Polyvinyl Chloride (CPVC)

Part - Union Nut

Pcs - 2

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF), and Chlorinated Polyvinyl Chloride (CPVC)

Part - Seat

Pcs - 1

Material - Ethylene Propylene Diene Monomer (EPDM) and Viton®

Part - Seat Carrier O-Ring

Pcs - 1

Material - Ethylene Propylene Diene Monomer (EPDM) and Viton®

Part - Solid End O-Ring

Pcs - 1

Material - Ethylene Propylene Diene Monomer (EPDM) and Viton®

Part - Flanged Cut

Pcs - 1

Material - Polyvinyl Chloride (PVC), Polypropylene (PP), Polyvinylidene Fluoride (PVDF), and Chlorinated Polyvinyl Chloride (CPVC)

Part - Foot Valve Assembly

Pcs - 1

Material - Polyvinyl Chloride (PVC)

|

|

Flow Coefficient Value (Cv)

|

N/A

10

|

N/A

25

|

N/A

38

|

N/A

76

|

N/A

80

|

|

Body/Union Nut/End Connectors

|

N/A

Polyvinyl Chloride (PVC), Chlorinated Polyvinyl Chloride (CPVC), ASTM D-1784

Polypropylene (PP), ASTM D-4101

Polyvinylidene Fluoride (PVDF), ASTM D-3222

|

|

Ball

|

N/A

Polyvinyl Chloride (PVC), Chlorinated Polyvinyl Chloride (CPVC), ASTM D-1784

Polypropylene (PP), ASTM D-4101

Polyvinylidene Fluoride (PVDF), ASTM D-3222

|

|

Seal/Seat

|

N/A

Ethylene Propylene Diene Monomer (EPDM)

Fluorocarbon, Viton® (Dupont Dow Elastomers)

Fluorel (3M Corp.)

|

|

Socket

|

N/A

ASTM - D-2467 (Polyvinyl Chloride (PVC), SCH-80)

ASTM, F-437 (Chlorinated Polyvinyl Chloride (CPVC), SCH-80)

|

|

Threaded

|

N/A

ASTM - D-2464 (Polyvinyl Chloride (PVC), SCH-80)

ASTM, F-437 (Chlorinated Polyvinyl Chloride (CPVC), SCH-80)

|

|

Flanged

|

N/A

ANSI - B16.5 Class 150

|

|

Features

|

N/A

- Less than 1 psi Pressure to Operate

- Operates in Vertical or Horizontal Installations

- One Piece Seat & Seal

- Excellent Flow characteristics

|

|

Additional Information

|

N/A

A molded gasket seal and seat enlarges seating surface and facilitates maintenance. Valves require less than one (1) PSI to open and 3 -5 PSI to close drop tight. Valves are capable of installation in either vertical or horizontal pipe run. Valves are readily adaptable for foot valve service with the addition of a screen assembly.

|

|

Note

|

N/A

Not recommended for compressed air or gas service.

|