| Items |

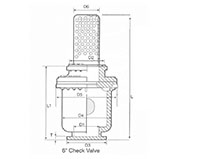

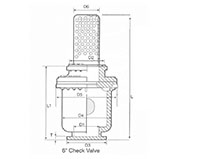

DN-6

6 Inch (in) Ball Check Valve

|

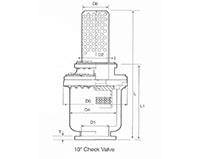

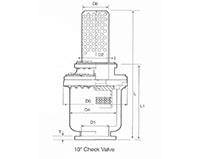

DN-10

10 Inch (in) Ball Check Valve

|

|

Description

|

N/A

Ball Check Valves (6") are of all thermoplastic construction, 10" bodies are fiberglass. The Body has full length ribs for maximum flow, minimum pressure drop, and to eliminate ball sticking and chatter. Ball is of solid thermoplastic material. In 6" size. In 10" size screen is PVDF.

|

|

Brands

|

N/A

TVI

|

|

Size

|

N/A

6 in

|

N/A

10 in

|

|

Dimension D1

|

N/A

5.91 in

|

N/A

9.48 in

|

|

Dimension D2

|

N/A

9.49 in

|

N/A

14.17 in

|

|

Dimension D3

|

N/A

11.10 in

|

N/A

16.14 in

|

|

Dimension n

|

N/A

8 in

|

N/A

12 in

|

|

Dimension e

|

N/A

0.87 in

|

N/A

0.91 in

|

|

Dimension L

|

N/A

30.94 in

|

N/A

46.85 in

|

|

Dimension T

|

N/A

0.91 in

|

N/A

1.34 in

|

|

Dimension D4

|

N/A

9.37 in

|

N/A

19.21 in

|

|

Dimension D5

|

N/A

14.37 in

|

N/A

23.62 in

|

|

Dimension D6

|

N/A

6.59 in

|

N/A

10.51 in

|

|

Dimension L1

|

N/A

18.70 in

|

N/A

27.05 in

|

|

Working Pressure

|

N/A

85 psi

|

N/A

42 psi

|

|

Materials of Construction1

|

N/A

Part - Flange End

Pcs - 1

Material - 6" Polyvinyl Chloride (PVC) (10"-PPG)

Part - Seal

Pcs - 1

Material - Ethylene Propylene Diene Monomer (EPDM), Viton®

Part - Ball (6") screen (10")

Pcs - 1

Material - 6" Polyvinyl Chloride (PVC) (10"-Polyvinylidene Fluoride (PVDF))

Part - Body

Pcs - 1

Material - 6" Polyvinyl Chloride (PVC) (10"-FRP)

Part - Hardware

Pcs - 1

Material - 304 Stainless Steel

Part - Foot Valve Assembly

Material - Polyvinyl Chloride (PVC)

|

|

Flow Coefficient Value (Cv)

|

N/A

1215

|

N/A

3800

|

|

Body/Union Nut/End Connectors

|

N/A

Polyvinyl Chloride (PVC), ASTM D-1784

Polypropylene (PP), ASTM D-4101

Polyvinylidene Fluoride (PVDF), ASTM D-3222

Fiber Reinforced Plastic (FRP), ASTM

|

|

Ball/Screen

|

N/A

Polyvinyl Chloride (PVC), ASTM D-1784

Polypropylene (PP), ASTM D-4101

Polyvinylidene Fluoride (PVDF), ASTM D-3222

|

|

Seal/Seat

|

N/A

Ethylene Propylene Diene Monomer (EPDM)

Fluorocarbon, Viton® (Dupont Dow Elastomers)

Fluorel (3M Corp.)

|

|

Flanged Only

|

N/A

ANSI - B16.5 Class 150

|

|

Additional Information

|

N/A

Seat is full circle and resilient. A molded gasket seal and seat enlarges seating surface and facilitates maintenance. Valves require less than one (1) psi to open and 3-5 psi to close drop tight. Valves are capable of installation in either vertical or horizontal pipe run. Valves become foot valves by attaching a screen assembly.

|

|

Note

|

N/A

Not recommended for compressed air or gas service.

|